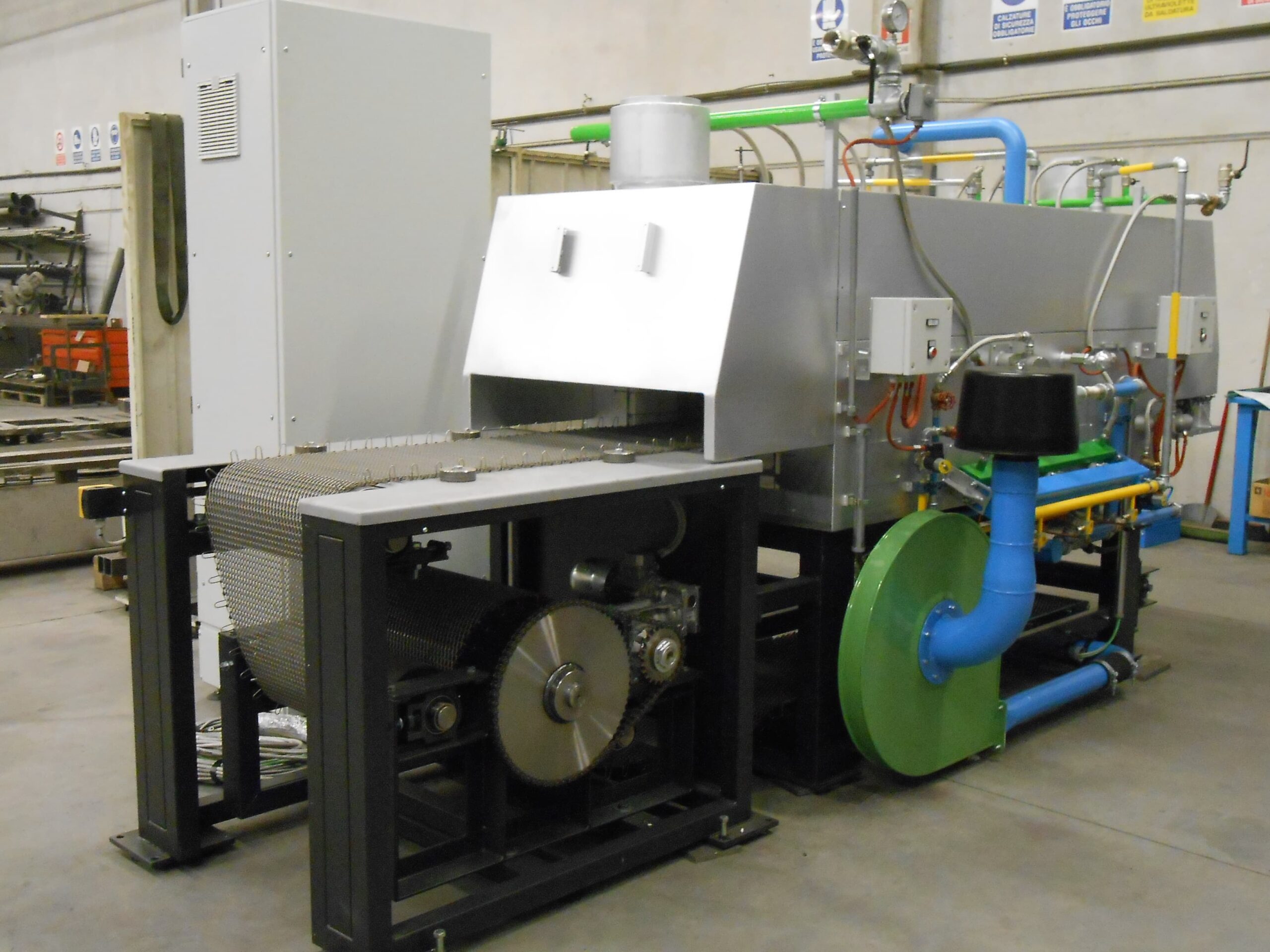

Our thermal stripping furnaces eliminate plastics, sand binders and every temperature-sensitive impurity from molten metals, rubber and plaster. This special thermal stripping treatment ensures that treated pieces don’t deform.

Among our plants, the typical thermal stripping furnace for metals, continuous or static, is built to retain gases and consists of 3 different sections, that communicate with each other, and each one works at a different temperature:

- principal combustion chamber: in this section, combustion fumes are produced through a burner, and they heat the following evaporation chamber.

- evaporation chamber for binders: this section of the thermal stripping furnace contains the pieces that have to be treated. The heating takes place thanks to the combustion fumes that come from the combustion chamber. The temperature of the evaporation chamber depends on the type of binder or varnish that has to be eliminated.

- post-combustion chamber: this section receives the combustion and carbon fumes from the previous evaporation chamber, obtained through the thermal decomposition, and eliminates them at a high temperature using a heating burner or electrical resistors and air. The final result of the combustion process consists of non-flammable and non-polluting gases, in addition to a little bit of oxygen that was previously added through the outside air.

Contact us for further information about our thermal stripping furnaces: call us or send an email to info@sabeforni.it to discover all the characteristics of our plants and receive a personalized consultancy.