Solubilization furnaces for non-ferrous metals are used for the annealing treatment of brass blanks among the following deep drawing processes to which they are subjected for the production of cartridges.

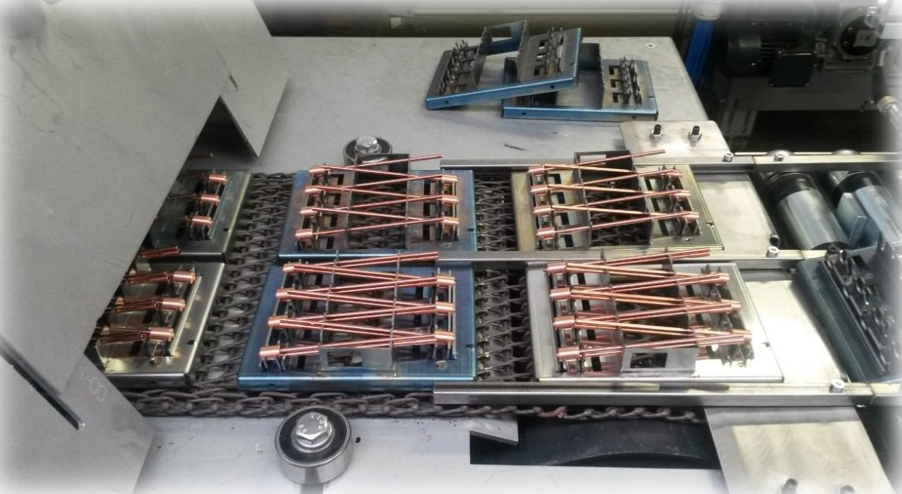

Continuous furnaces with conveyor belt and nitrogen atmosphere with possible addition of small amounts of hydrogen are used to produce small elements and fittings. All the pieces must be kept at high temperature (about 700°C) for the shortest possible period, in order to avoid the evaporation of zinc that would cause the depletion of the alloy. Also finished cartridges are annealed with the same treatment, followed by a phase of distension with ventilated air. Bigger elements are treated inside static or humpback solubilization furnaces for non-ferrous materials with neutral atmosphere.

Brass tubes are usually annealed with air inside ventilated continuous annealing furnaces for non-ferrous materials. This causes a superficial oxidation that has to be removed with a subsequent pickling process. The light superficial oxidation limits the migration towards the surface and the evaporation of zinc, preserving the required colour after the pickling process.

Silver sheets, belts, objects made of precious metals are annealed inside continuous furnaces in an atmosphere of nitrogen-hydrogen (4% or higher) or inside chamber furnaces if they have bigger dimensions.

Learn more about our annealing furnaces for non-ferrous materials and contact our experts.