Multiple possible heat treatments, multiple plants

Sabe Forni offers a variety of industrial furnaces for heat treatments, diversifying its production to better meet the specific needs of different sectors such as: metallurgy, automotive, design, etc.

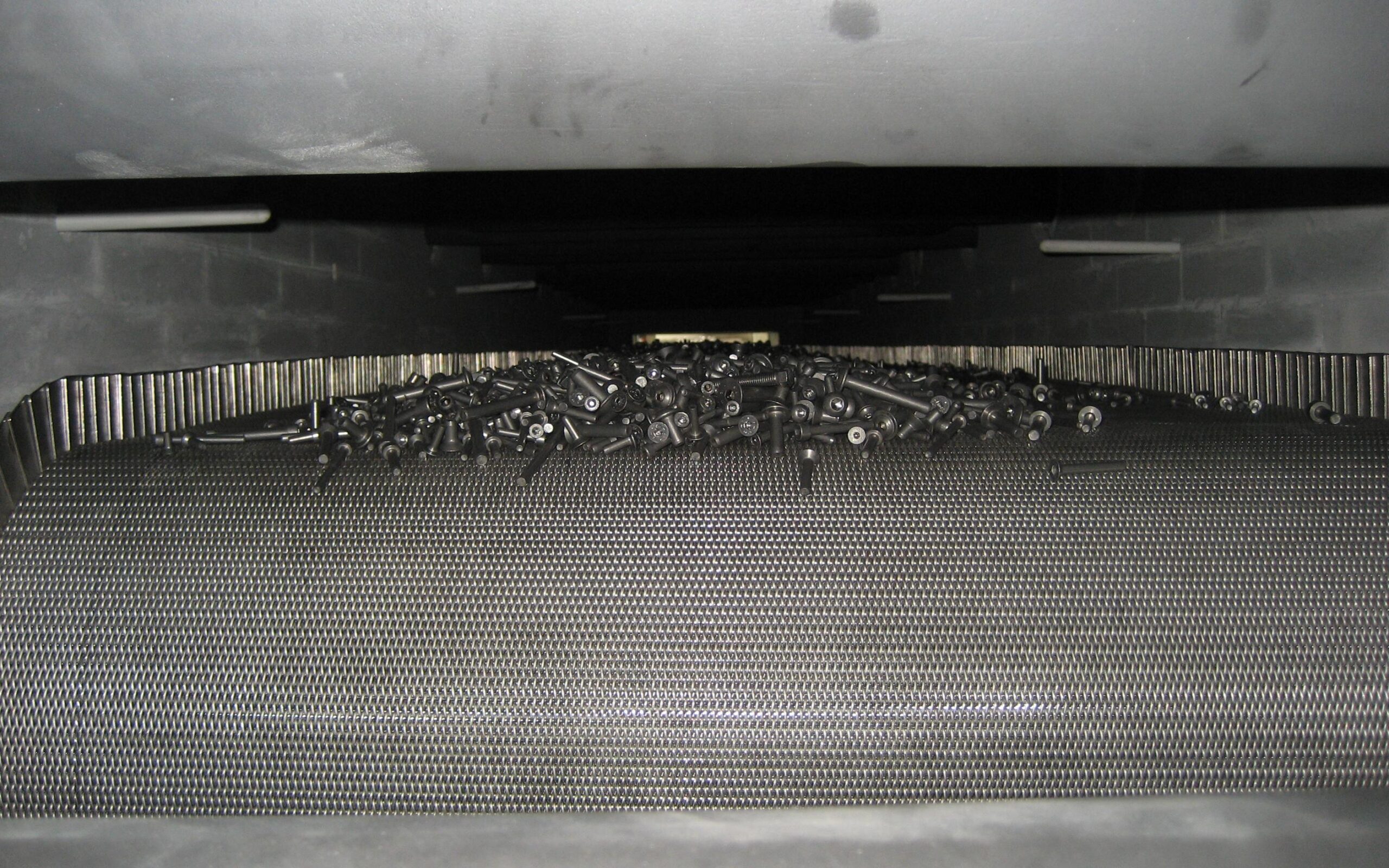

Our wide and diverse range of industrial furnaces, with conveyor belts or rollers, derives from a big variety of possible heat treatments and from the different characteristics (dimensions, materials, etc.) of the components that have to be treated. Moreover, we are equipped with all the specific tools to perform treatments both on the surface (carburizing, nitriding) and in the interior part of components (hardening).

Shutdown fluids inside heat treatment furnaces

Shutdown fluids vary inside our industrial furnaces for heat treatments according to the materials that have to be treated and their hardenability: water, water with polymers, molten salts, oil, gas.

Protective atmosphere inside heat treatment furnaces

Some treatments need an accurate control of the protective atmosphere, through the measurement and the adjustment of gaseous components. For this reason, we offer industrial furnaces equipped with a specific system that analyses the presence of gases using infrared or paramagnetic measuring cells.

Auxiliary systems for heat treatment furnaces

Our furnaces for the heat treatment of steel and metals are often complemented by auxiliary systems, such as electronic weighing loaders, oil removal equipment, bluing tanks, etc. that complete our supply of products and make the execution of complex processes possible.

Gas nitriding furnaces

Nitriding is a treatment to harden the surface of the components and can reach very high hardness values, from 600 to 1100 Vickers. The element that has been treated with the nitriding process has a greater resistance to wear and stress. It is a treatment that takes place at low temperature (lower than 600°C) and doesn’t cause strong geometric deformations.

The nitriding process takes place in two phases:

- the first phase takes place at a stable temperature between 500 and 530°C, and the degree of dissociation is kept between 15% and 30%;

- the second phase takes place at a temperature of 550-565°C and the degree of dissociation increases to 65-80%.

In this way, you can obtain an extremely hard and compact surface made of an outer white layer with a thickness of 5-25 micron, where nitrogen creates iron nitrate (Fe2N), and an inner layer called “diffusion zone” with a thickness between 0.1 and 1 mm characterized by a high level of hardness and a better resistance to stress.

The degree of dissociation is controlled by the addition of ammonia that has been previously dissociated inside a dissociator contained in the plant. Waste gases, that are emitted into the atmosphere and contain non-dissociated ammonia, are treated inside another dissociator to obtain the complete combustion, and avoid the presence of toxic gases in the environment.

With our industrial furnaces for heat treatments, it is possible to realize the following processes:

- Hardening (inside water, oil, molten salt)

- Tempering

- Carburizing

- Carbonitriding

- Gas nitriding

- Hardening of solutions – Aluminium

- Aging of aluminium