The Brazing furnaces

Brazing furnaces are similar each other and differ only for the working temperature and the protective atmosphere. In some cases, atmosphere may be produced in the furnace itself without using external generators.

-

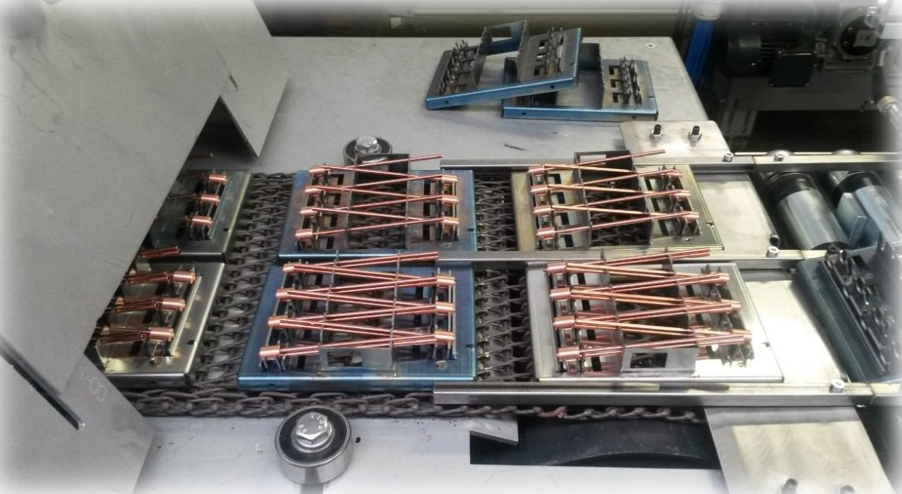

Conveyor belt continuous brazing furnaces

Traditionally, conveyor systems in continuous brazing furnaces are performed by belts. AISI 330 e l’AISI 314 are often use to produce these kind of conveyor belts and their shape has to be specifically studied for the pieces to be treated.

-

Ceramic rollers continuous brazing furnaces

Ceramic rollers are a possible alternative to the belts. The innovative system studied by Sabe Forni allows a huge saving of costs and improves quality of products. The Sabe Forni roller conveyor system is designed to work even in hydrogen.

-

Static brazing furnaces

Certain productions require a static heat treatments plant, where conveyor systems are not necessary to move items during treatments.

-

Brazing furnaces with controlled atmosphere

Protective atmosphere in heat treatment furnaces can be reached inside the furnace itself, without external generators. This option has to be evaluated during quotation phase.

-

Furnaces for Brazing aluminium alloys

A slightly different technology is used for brazing aluminum alloys, which require: pastes containing light-brazing fluxes, elimination of water contained in the flux itself, flash for cleaning the surfaces and then the real brazing. These operations are carried out at different temperatures. The filling material is a silicon-aluminum alloy powder or, for pieces with same material plating surface, with a melting point lower than the base metal.

Filling materials normally used are pastes, preformed pieces of wire or electrodes of copper, nickel-chromium, copper-phosphorous, copper-tin or silver alloys. Controlled atmospheres usually eliminate the need of deoxidizers, often corrosive or harmful.

Thanks to the implementation of new technologies, these industrial brazing furnaces do not require corrosive or, in any case, potentially harmful, boning agents, helping to improve the safety of the plant.

Finally, our production also includes the following types of brazing furnaces:

- Furnaces for brazing carbon steel

- Brazing stainless steel furnaces

- Brazing copper furnaces

- Brazing bronze furnaces

- Brazing brass components